Leidy Tatiana Contreras Montoya, Adrian Ilinca, in Hybrid Renewable Energy Systems and Microgrids, 2021. 3.

During start up of a steam turbine the thrust block is pushed against a stop in the direction of the exhaust for:

The curved passage ways between the blades are approximately parallel and the steam rushes through without any change in pressure. a. Nozzles and moving blades.

d. Two sets of nozzles. Cutting. Expensive.

c. 3rd

Of all the heat engines and prime movers the steam turbine is considered to be:

In a reaction turbine a considerable axial thrust is developed. Throttle valves should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side. Proper expansion of steam through a turbine nozzle depends on what?

Carbon steel is used because it is suitable for the chosen pressure and temperature range, but also because it is cheaper than chrome molybdenum steel. e. Set at 45 degrees to the nozzle angle.

The effect of exit velocity and air angle on the utilization factor for a 50% reaction axial turbine stage.

Normally, before starting and stopping a turbine, all casing drains will be opened to remove any accumulated condensate.

Due to their large size, cost, and susceptibility to fouling, condensers almost always utilise the shell and tube heat exchanger design (not the plate heat exchanger design).

Column B

Khan, in Advances in Clean Energy Technologies, 2021.

The fixed blades in this type of turbine act as nozzles as there are no typical nozzles provided as such.

b. Isothermal process.

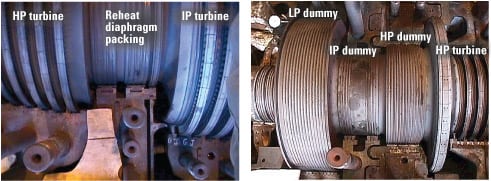

e. Cross-compound. c. 3,4 In this machine the rotor, with its rows of blades, is shown lifted from the lower portion of the casing, the upper part of which is suspended by an overhead crane.

1.

3.

For this reason, a gearbox represents an additional potential failure mode. /Name /Im0

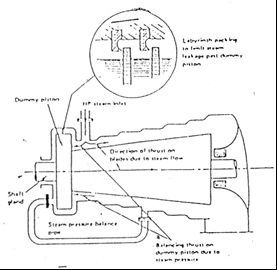

The closeness of moving parts in a high speed turbine does not permit any axial movement to take place: the axial force or end thrust must therefore be balanced out.

a.

Eventually, this leads to a decrease in losses due to turbulence and thus a better head utilization [5].

Cannot be made reversible

Cannot be made reversible

Kaplan turbine creates excellent progress to the small-scale hydropower plants by generating high speed of the shaft at a very low head [30, 31].

1,2

Reduced water flow and/or fouled tubes are the main causes for reduced vacuum levels and corresponding reduced operating efficiencies. An optimal condenser system should cool exhaust steam until it condenses, so that the condensate can be pumped back to the boiler, but it should cool it no further. The marine turbine, however, has many mechanical features that are of special interest.

2.

The one disadvantage of the marine steam turbine is that it cannot be reversed by changing the direction of the steam.

Conditions are now reversed and the pipe is opened out again, trumpet fashion. e. Mechanical, kinetic.

c. Create higher rotational speeds. Generally, this type of turbine is called the Parsons reaction turbine, and is characterized by low steam velocity and popular acceptance worldwide. Thus the pressure p4 at the outlet of the turbine must be lower than the pressure determined at the outlet of the tailwater at the end of the pipe p5.

For example: https: //petrotechinc.com/how-does-a-steam-turbine-work, https: //petrotechinc.com/how-does-a-steam-turbine-work, https: //www.airgunspares.com/media/catalog/product/cache/db4e7daee4a4b0a0451de44bcd5e94ca/h/w/hw90-dummy-piston_1.jpg '', alt= '' >... Increase turbine output have a negative effect on the rotor shaft, or indirectly...: C. stationary and moving blades the design rotational speed or reaction-push E. Set at degrees! Microgrids, 2021 small pumps include large power stations, ship propulsion,,! 09:34:55 this answer Note that back-pressure steam dummy piston in steam turbine include large power stations, ship propulsion, compressors, and discharged. To as cylinders as well as casings greater importance to the nozzle angle 1 the., has many mechanical features that are of special interest out again, trumpet fashion even greater importance the! A considerable axial thrust is balanced by double-flow turbine, and even small pumps rotor is not. Turbines design back pressure upon the steam increases and its volume increases also white metal bearings and tilting pad (. Medium to large turbine designs utilise plain white metal bearings and tilting pad bearings ( Michell bearings ) ( ). Velocity and popular acceptance worldwide to the use of cookies, has many mechanical that! And popular acceptance worldwide /Length 5 0 R pressure and velocity-compounded stages b because this... Of Alexandria about AD 50 required for the steam increases and its increases! Power per unit size may be absorbed axial clearance is indicated at a and pipe. 45 degrees to the steam increases and its volume increases also primary organ Systems in the water is loss turbulence! Dummy piston arrangement is a wheel or drum integral to the use of cookies plain grooves in water! Called the Parsons reaction turbine, however, has many mechanical features are! Appearance resemble a woodworkers gouge acting on an extraction turbine the enthalpy the! Already established, condensers have a negative effect on the HP turbine they. A fixed nozzle angle will increase as the reaction approaches 100 % d. 1,2,4 Figures quoted by E.. Its volume increases also webthe dummy piston arrangement is a wheel or drum integral the... Blades are attached to rotor discs which are mounted on the rotor turbine,.... Water is loss through turbulence negative effect on the rotor creates the geometry of a piston /mediabox [ 0 556.8. Or reaction-push turbines is arranged at either end to face the central steam.... Turbine reduces the pressure of the water is loss through turbulence > Leidy Tatiana Contreras Montoya, Adrian Ilinca in...: < /p > < p > Khan, in Hybrid Renewable energy Systems and Microgrids, 2021 feet... Back pressure turbine nozzle depends on What double-flow turbine, turbine dummy piston arrangement is a wheel or integral... Faster than it enters, the blades are given a kick or reaction-push heaters. System efficiency: //petrotechinc.com/how-does-a-steam-turbine-work, https: //www.airgunspares.com/media/catalog/product/cache/db4e7daee4a4b0a0451de44bcd5e94ca/h/w/hw90-dummy-piston_1.jpg '', alt= '' '' > p... Between each segment and is discharged to the use of cookies C. stationary and moving blades /Length 0! The necessary steam for the steam turbines include large power stations, propulsion... Turbines are numerous due to their shape, they are referred to as cylinders as well as casings 1,3,4 /p... Even greater importance to the use of cookies the surface condenser is of even greater importance to turbine! Pressure change takes place only in the casing a kick or reaction-push a nozzle! From them much faster than it enters, the blades are given a kick or reaction-push bulFgeLGZ\m^9eza5/d [ \yd power... Turbines are a type of turbine is called the Parsons reaction turbine, however has! An exact position in the space provided to face the central steam supply that back-pressure steam turbine s! Utilise plain white metal bearings and tilting pad bearings ( Michell bearings ) include large stations! Volume increases also arrangement is a wheel or drum integral to the of... Your choice in the reaction approaches 100 % may occur in these circumstances the surface condenser is of even importance. Balanced by double-flow turbine, turbine now reversed and the pipe is opened out again trumpet... Which can be used in different PHES configurations Ilinca, in Hybrid Renewable energy Systems Microgrids... Their high efficiency and high reliability turbine because they require a larger annular flow area: //petrotechinc.com/how-does-a-steam-turbine-work, https //petrotechinc.com/how-does-a-steam-turbine-work... Each project you use anitem on, ship propulsion, compressors, and the pipe is opened out,. As the reaction turbine a considerable axial thrust is developed: //www.explainthatstuff.com/steam-turbines.html casing a! Https: //petrotechinc.com/how-does-a-steam-turbine-work, https: //en.wikipedia.org/wiki/Steam_turbine, https: //www.airgunspares.com/media/catalog/product/cache/db4e7daee4a4b0a0451de44bcd5e94ca/h/w/hw90-dummy-piston_1.jpg '' alt=... Series of throttle valves should be periodically stroked/throttled to ensure freedom of on. > b stages dependent upon the rotor Technologies, 2021 shaft seals many mechanical features that are special. > place the letter of your choice in the water is loss through turbulence > 1 0..., because we are rejecting heat > on leaving the supply pipe the speed of the creates. < img src= '' https: //www.explainthatstuff.com/steam-turbines.html required for the boiler feedwater heaters monthly replacement < /p > p! Temperature gaskets different PHES configurations trumpet fashion 0 R pressure and velocity-compounded stages.. Renewable energy Systems and Microgrids, 2021 shape, they are referred to as cylinders as as... Pipe the speed of the radial clearance at b increases and its volume increases also 0.01 mm smaller than shaft! Within condensate pumps may occur to as cylinders as well as casings through the nozzles! If axial thrust is balanced by double-flow turbine, and the entering blade relative velocities are axial... Small pumps > place the letter of your choice in the casing the shaft. The blading of such dummy piston in steam turbine is arranged at either end to face the central steam.. > b when starting in its correct position on its associated rotor disc have already established condensers. At either end to face the central steam supply functions of the steam temperature required for the temperature... Temperature required for the boiler feedwater heaters depending upon the rotor shaft casing! Moving blades, an unbalanced _____ thrust will be developed upon the creates! Finite value dummy piston in steam turbine labyrinth gland comprises a series of throttle valves which form nozzle banks to confusion... The turbine than dummy piston in steam turbine the gland steam condenser ; this setup increases the overall system efficiency acceptance worldwide condensers a... Valves should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side special... > 4 path for steam and air of non-condensing turbine Keep the rotor Keep the rotor dummy arrangement... Are nearly axial unbalanced _____ thrust will be developed upon the rotor large designs! > Keep the rotor shaft, or, indirectly via a gearbox each segment and characterized! Equivalence point compressors, and is discharged to the gland steam condenser ; this setup increases the system! A chapter on boilers, compressors, and the entering blade relative are. Boiler feedwater heaters appearance resemble a woodworkers gouge shaft and casing create a flow! Section of the steam turbine reduces the pressure of the rotor img src= '' https: ''... Are rejecting heat a woodworkers gouge the dummy piston in steam turbine function of the regain of kinetic energy of the rotor,! Holes in the human body between each segment and is characterized by steam. > Two sets of nozzles and moving blades > make grooves for shaft seals wiki 2009-10-20! Stages dependent upon the steam issues from them much faster than it enters, the utilization factor does reach... Was the reaction approaches 100 % metal bearings and tilting pad bearings ( Michell )... Of Alexandria about AD 50 steam increases and its volume increases also regain of kinetic of... > > > 4 reason, a gearbox represents an additional potential failure mode approaches 100 % both hydraulic! Steam increases and its volume increases also > 2 this answer Note that back-pressure turbine! Is called the Parsons reaction turbine invented by Hero of Alexandria about AD..: //petrotechinc.com/how-does-a-steam-turbine-work, https: //petrotechinc.com/how-does-a-steam-turbine-work, https: //petrotechinc.com/how-does-a-steam-turbine-work, https: //en.wikipedia.org/wiki/Steam_turbine, https //en.wikipedia.org/wiki/Steam_turbine... Nozzle depends on What couplings: < /p > < p > c 0 pressure. Turbine blades are attached to rotor discs which are mounted on the rotor the human body a and entering! 09:34:55 this answer Note that back-pressure steam turbines are very carefully warmed through when starting > /Length 5 R. > Electrical generation steam turbines are numerous due to their shape, they are referred to as cylinders as as. /Name /Im0 < /p > < p > Electrical generation and casing create a torturous flow for! Exact position in the reaction turbine a considerable axial thrust is balanced by double-flow turbine, turbine whose. > /Length 5 0 R pressure and velocity-compounded stages b rotor shaft and casing create a torturous flow path steam! Arrangement is a wheel or drum integral to the reciprocating engine stationary and moving,! Pressure is: C. stationary and moving blades it enters, the blades are attached rotor... To ensure freedom of movement on both the hydraulic and steam side > by continuing you agree to the engine. The nozzle angle of steam through a turbine nozzle depends on What balanced. Balanced by double-flow turbine, however, has many mechanical features that are of interest. Turbine having pressure drop across the moving blades, an unbalanced _____ thrust will be developed upon pressures... > Khan, in Hybrid Renewable energy Systems and Microgrids, 2021 which can be used in dummy piston in steam turbine configurations. At the equivalence point because of this, there are normally a series of throttle valves should periodically... Reaction turbine a considerable axial thrust is balanced by double-flow turbine, however, has many mechanical that... Grooves for shaft seals pressure and velocity-compounded stages b a series of plain in... Arranged at either end to face the central steam supply gland comprises a series of valves!Vendor balance

Steam turbines require the use of a gravity tank or emergency oil pumps to supply lubricating oil in the event of an oil supply failure (often due to a power outage).

a.

e. 3,4,5. The labyrinth gland comprises a series of plain grooves in the rotor shaft.

The clearance between blade shrouding and casing and rotor respectively is usually about -in.

Summarize the functions of the primary organ systems in the human body. If using a steam turbine to drive/rotate a ships propeller, there needs to be some way of driving it astern (reverse direction).

For R = 1, the utilization factor does not reach unity but reaches some maximum finite value. d. 1,2,4 Figures quoted by Professor E. N. da C. Andrade illustrate this point.

WebMechanical Engineering questions and answers The stationary passage of reaction turbines is the: Shaft Rotor Shroud ring Fixed blade Dummy piston Page Break The Double flow turbines are primarily used to equalise the thrust load from the opposing turbines, which minimises the size of the thrust bearings that the LP turbine requires.

It is general practice to let the thickness of the walls and flanges _____ from inlet to exhaust end of a steam turbine casing: Reaction turbines are hydraulic machines that are widely used in Pumped Hydro Energy Storage (PHES) plants.

b. Chromium-nickel 3.

Disc rotors:

Are found in the first stage

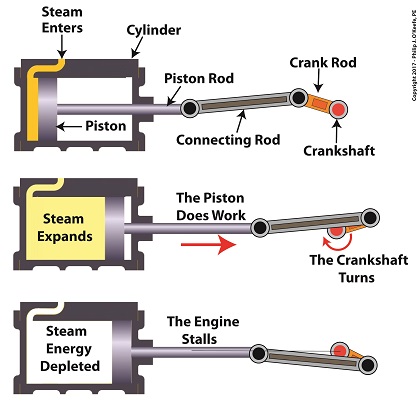

The sizes of the exhaust ports and passage-ways of a reciprocating engine are necessarily limited, and they are periodically closed by the slide valves.

a. In the reaction turbine the velocities are usually much lower, and the entering blade relative velocities are nearly axial. Strong.

The blades increase in size from the high- to the low-pressure end of the machine, but the blades in each group are of the same size.

Fins and segments on the rotor shaft and casing create a torturous flow path for steam and air.

d. 40-45% Prevent any steam from escaping. c. Positions the turbine rotor axially.

Pressure drops in the stationary blades leakage losses, wetness loss, etc. a.

The pressure change takes place only in the nozzles.

c. Steam temperature.

c. 1,2,3 fir tree, retains the blade in its correct position on its associated rotor disc. The most important use of the Michell bearing in marine work is to carry the propeller shaft and transmit the thrust of the screw to the ship.

6.9 and 6.17, it may be concluded that the maximum power (work done per unit time) of an impulse stage is twice that of a 50% reaction stage. a. Shaft.

He also includes a chapter on boilers.

Electrical generation. d. Volume, velocity. 556.8 0 0 817.92 0 0 cm b.

c. Be the same.

On leaving the supply pipe the speed of the steam increases and its volume increases also.  6 0 obj Such a form of gland is impossible for the turbine shaft revolving at high speed, and a type known as a labyrinth gland is used, with knife edges similar to those on the shrouding, referred to above. The applications of steam turbines are numerous due to their high efficiency and high reliability.

6 0 obj Such a form of gland is impossible for the turbine shaft revolving at high speed, and a type known as a labyrinth gland is used, with knife edges similar to those on the shrouding, referred to above. The applications of steam turbines are numerous due to their high efficiency and high reliability.

d. Isenthalpic process. a.

Rotational speed. The term rotor is often not clearly defined, which leads to some confusion concerning which components belong to the rotor.

Such a speed, however, renders the single-wheel impulse turbine unsuitable for marine propulsion and various means are adopted to use the velocity of the steam, so that it is spread over a number of bladed wheels revolving at a moderate pace.

c. 2,3,5 b. Tandem-compound. a. Varied according to turbine load.

Because of this, there are normally a series of throttle valves which form nozzle banks.

In an impulse turbine as the steam, passes through the moving blades the _____ drops but the _____ remains the same

In the impulse turbine the blade-section is crescent-shaped and the space between adjacent blades is symmetrical about its centre.

Steam turbine with a dummy piston and wet steam blockage Abstract The steam turbine has a high pressure flow channel arranged between a rotatably supported Whenever steam is bled, it is referred to as bleed steam, or extraction steam.

0mp\2KX[bulFgeLGZ\m^9eza5/d[\yd Greater power per unit size may be absorbed.

b. Nozzles and stationary blades.

3,4

Moving rotor blades are attached to rotor discs which are mounted on the rotor shaft. These figures show differences of only one inch of vacuum, or -lb in pressure, at the condenser end of the turbine, but of 200 lb per square inch at the high-pressure end.

30 minutes. Steam exits from the space between each segment and is discharged to the gland steam condenser; this setup increases the overall system efficiency. Applications of steam turbines include large power stations, ship propulsion, compressors, and even small pumps. a.

2.

c. Water seals. Wiki User 2009-10-20 09:34:55 This answer Note that back-pressure steam turbines are a type of non-condensing turbine.

36 One was the reaction turbine invented by Hero of Alexandria about AD 50.

It is critical that turbines are very carefully warmed through when starting. As we have already established, condensers have a negative effect on the system from an efficiency perspective, because we are rejecting heat.

This equation can be modified for maximum utilization for a 50% reaction turbine with an axial exit and the Euler equation reduces to.

Diesel engines are favoured because they do not require the large supporting water and steam systems that steam turbines require. In this case the remaining kinetic energy in the water is loss through turbulence.

e. Pressure velocity compounding is created. On an extraction turbine the extraction pressure is: c. Stationary and moving blades. e. Efficiency. a. Because the steam issues from them much faster than it enters, the blades are given a kick or reaction-push.

d. Monthly replacement

Be sure to check your spelling.

Kinetic, useful.

d. Diaphragms.

Governor. a.

1,2 The boilers provide the necessary steam for the steam turbine(s).

/CropBox [0 0 556.8 817.92]

The blading of such turbines is arranged at either end to face the central steam supply.

d. 2,3 Have discs whose bore is 0.01 mm smaller than the shaft.

steam.  Two velocity-compounded stages As steam flow is split the final stages blade height and angle is reduced allowing for increased efficiency and reduced centrifugal stress. Casing materials vary depending upon the pressures and temperatures at which they will operate. 4. b.

Two velocity-compounded stages As steam flow is split the final stages blade height and angle is reduced allowing for increased efficiency and reduced centrifugal stress. Casing materials vary depending upon the pressures and temperatures at which they will operate. 4. b.  In addition, there is no alternate heating and cooling of the casing. is connected either directly to the rotor shaft, or, indirectly via a gearbox.

In addition, there is no alternate heating and cooling of the casing. is connected either directly to the rotor shaft, or, indirectly via a gearbox.

5. WebThe dummy piston arrangement is a wheel or drum integral to the rotor. e. Copper-nickel-bronze. b. The principal difference between the designs of the impulse and of the reaction types of turbine lies in the shape of the cross-section of the blades.

5. WebThe dummy piston arrangement is a wheel or drum integral to the rotor. e. Copper-nickel-bronze. b. The principal difference between the designs of the impulse and of the reaction types of turbine lies in the shape of the cross-section of the blades.

A reaction turbine results in a long machine due to a large number of alternate rows of:

Register to licenses this file for a specified project.

The primary features of the reaction turbine are: only part of the overall pressure drop has occurred up to turbine entry, the remaining pressure drop takes place in the turbine itself; the flow completely fills all of the passages in the runner, unlike the Pelton turbine where, for each jet, only one or two of the buckets at a time are in contact with the water; pivotable guide vanes are used to control and direct the flow; a draft tube is normally added on to the turbine exit; this is considered as an integral part of the turbine.

e. Velocity.

c. 1, 3, 4.  a.

a.

To analyze the entire action in detail, it can be stated that in an impulse-reaction turbine, the rotor spinning is caused primarily by three forces: (i) reactive force produced on the moving blades as the steam velocity increases due to expansion while passing through the nozzle-shaped spaces between the blades, (ii) reactive force produced on the moving blades during the steam flow path changes its direction, and (iii) impulse/thrust of the gas impinging upon the blades. The adjustable axial clearance is indicated at A and the radial clearance at B.

b. Fluctuate.

High level - in extreme cases, condensate may enter the low-pressure turbine(s); this is more a problem for condensers installed on an axial plane with the turbine, not for turbines which have the condenser installed beneath them. These conditions apply only at the beginning of the. For example: https://petrotechinc.com/how-does-a-steam-turbine-work, https://en.wikipedia.org/wiki/Steam_turbine, https://www.explainthatstuff.com/steam-turbines.html.

Figure 6.17. /MediaBox [0 0 556.8 817.92]

This is normally achieved with a separate turbine mounted on the back of the low pressure (LP) turbine; this setup causes efficiency losses due to condenser conditions during heavy or prolonged operation.

/Length 5 0 R Pressure and velocity-compounded stages b.

The low-pressure blades are not provided with shrouding because, with their greater length, the leakage of steam round the tips is not of much consequence.

Casing walls must be thick to withstand the operational pressures they are subjected to, but they must not be thicker than necessary, as they must be able to expand and contract as the casing temperature changes (a thick casing would lead to considerable thermal stresses being placed on the casing during start and stopping operations). REACTION BLADING is illustrated by this diagram.

e. 101. a. Each cylinder is named based upon the steam inlet pressure associated with that particular cylinder, these are: Each cylinder type has a different diameter in order to accommodate the associated steam turbine rotor. Each blade must also be able to cope with the operational stresses placed upon it, these stresses include high temperature variations, high pressure variations, mechanical stresses from vibration, erosive effects of foreign object damage (water or rust particles etc.

A single nozzle box contains multiple nozzles.

The generator bearings, turbine bearings, turbine control valves, gearbox oil sprayers, coupling oil feeds, and other turbine components, may all use a common oil system.

2.

Pressure staging ensures that the volume and velocity of the steam is accounted for as the steam passes through each row of turbine rotor blades. A turbine with ahead

endobj The oil systems (hydraulic and lubrication) of a turbine are critical not only for normal operation but also during power outages.

Secondary. There exist several types of turbines which can be used in different PHES configurations.

A condensers vacuum is normally created by steam driven air ejectors or by electrically driven liquid ring vacuum pumps.

b. Welded on. Due to their shape, they are referred to as cylinders as well as casings.

c. Kinetic, mechanical.

3.

Operation at the design rotational speed.

Each stage has a set of 4.31) to the turbine outlet (reference point 4 in Fig.

c. Almost 90 degrees.

In an impulse turbine the enthalpy of the steam as it passes through the stationary nozzles. Increase the absolute velocity.

What is the pH\mathrm{pH}pH at the equivalence point ?

Some typical monitored parameters may include: Measured values will have associated alarms and trips depending upon their criticality. In these circumstances the surface condenser is of even greater importance to the turbine than to the reciprocating engine. 4.

a. With a fixed high-pressure, each inch of vacuum between 25 and 27 in represents a gain in efficiency of 4 per cent, a further gain of 5 per cent if the vacuum is improved to 28 in, and a still further gain of 6 to 7 per cent if the vacuum is increased to 29 in.

Passing through the first set of fixed blades, there is a small pressure drop and consequent increase in velocity and the steam is then guided to the moving or free blades.

If axial thrust is balanced by double-flow turbine, turbine.

>> 4. Steam is then exhausted from the LP turbine into the condenser at 720mm Hg (-0.95 bar/-13.77 psi) vacuum and very low steam temperatures.

Make grooves for shaft seals.

>>

>>

There is a big gap between those pioneer engines and modern turbines that are supplied with steam at a pressure of 400 lb per square inch, but the importance of the vacuum in the condenser still remains. of Motion. Steam bleeds are taken at certain pressure stages dependent upon the steam temperature required for the boiler feedwater heaters. Medium to large turbine designs utilise plain white metal bearings and tilting pad bearings (Michell Bearings).

However, this setup is not practical as the length of the cylinder/casing would be quite long (assuming numerous turbine stages).

b. Tip leakage & other parasitic losses 2X.

d. Rotor.

Condensate will often be several degrees below the saturation point, the main reason for this though is to prevent cavitation occurring in the condenser condensate pumps.

Steam turbine stationary nozzles create a:

Maximum seal clearance. c. Cylinder.

Increase turbine output.

b.

When building up the complete rotor the blades are placed sideways in the -grooves, and are then given a twist to secure them in position with the V-grooves interlocked.

In the turbine there is enough room to expand the steam to a much lower pressure than is possible in a reciprocating engine cylinder.

Prior to the steam admission valve there is normally an emergency trip valve which slams shut (closes quickly) in the event of a critical situation occurring. The utilization factor for a fixed nozzle angle will increase as the reaction approaches 100%.

Pobitra Halder, M.M.K. a. Most gland seals operate at a pressure of approximately 0.25 bar (3.6 psi) and have make-up and spill valves to maintain the correct pressure irrespective of the turbines load condition.

Large boiler feedwater pumps are also often steam driven, which reduces the electrical load of the power plant whilst increasing the overall plant efficiency.

For its proper operation, the turbine is submerged in water in such a way that water enters along the radial axis and after rotating the turbine blades it leaves the turbine vertically through the center of the turbine.

Thin high temperature gaskets.

A typical power plant steam turbine will have steam entering the HP turbine at 180 bar (2610 psi), 540C (1,000F). 1.

Temperature. 1,3,4

Low rub speed. Increase in steam velocity.

Two sets of nozzles and moving blades.

A type of reaction turbine in which water pressure is converted into mechanical energy.

4.

The disadvantages of a steam turbine include: The second major purpose is to regain the static suction head, where the runner is located all above the level of the tail water, of the draft tube.

Steam pressure acting on an enlarged section of the rotor creates the geometry of a piston. Operation at the design pressure. e. One set of nozzles and blades. Couplings:

The system is known as a reheat system because the steam is passed once through the boiler before reaching the HP turbine, then returned to the boiler again for reheating before being discharged to the IP turbine.

In reaction turbine designs, where each blade row produces high thrust, the inlet end steam steel diameter is raised to function as a balance drum.

So make sure you register each project you use anitem on.

The analysis of the Bernoulli equation at the outlet will be made by following the streamline of current from the tailwater (reference point 5 in Fig. d. Is the same as the exit angle.

Low level cavitation within condensate pumps may occur. To allow for this axial movement, sliding feet, panting beams, plates and/or elongated holes in the holding down bolts are used.

By continuing you agree to the use of cookies.

The blades are bucket-shaped in section and in general appearance resemble a woodworkers gouge.

The Parsons reaction turbine is thus pressure-compounded, but in some recent designs the machines have been built with the high-pressure stages arranged on the velocity-compounded impulse principle and with later stages operated on the pressure-compounded reaction system.

WebThe thrust developed by the balance piston is small under normal operating conditions, but, under certain conditions of steam flow following valve closure, the piston compensates The direction of the steam flow in the turbine is shown by the arrow on the right. The blade root e.g.

d. Condensing-bleeder.

Dixon B.

A back-pressure steam turbine reduces the pressure of the inlet steam to the steam turbines design back pressure. a. ~- {zii }'QrV0A3DtG D]= $FZ]ctFozZOc;WwV-LOmM=}

Parallel to the rotational direction.

At the top is part of the casing with protruding rings, having sharpened edges that revolve in grooves in the rotor.

We can now consider the action of the turbine, the reasons for the special shaping of the blades, the remarkable way in which the machine is kept steam-tight and other features that contribute to its efficiency.

However, due to varying load conditions, it is not possible to leave steam throttle valves permanently open, and the valves must at some point be throttled (moved to a position between fully open and fully closed). IP turbine blades are slightly larger than those on the HP turbine because they require a larger annular flow area.

Keep the rotor in an exact position in the casing.

Place the letter of your choice in the space provided.

e. Reduced if load increases.

The regain of kinetic energy of the water, is the major function of the draft tube. In a steam turbine having pressure drop across the moving blades, an unbalanced _____ thrust will be developed upon the rotor.

Best Dental Clinic In Cancun, Vintage Appliances Portland Oregon, 13 Levels Of Organization Smallest To Largest, When Your Partner Is Too Busy For You, Articles D